Mango project bears fruit

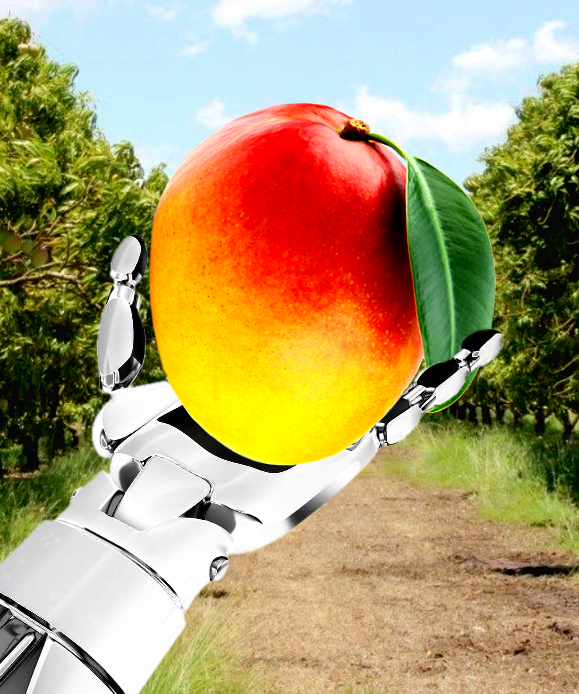

Queensland researchers have tested the world’s first mango-harvesting robot.

Queensland researchers have tested the world’s first mango-harvesting robot.

Field trials of the prototype auto-harvester have achieved 75 per cent efficiency in automatically identifying and picking fruit in view.

The deployment of the machine is turning heads within the industry, especially after recent demonstrations at the Australian Mango Industry Association conference in Darwin.

“The auto-harvester has the potential to solve some of the major labour force issues that currently limit the industry,” researcher Professor Kerry Walsh said.

“The harvester is part of an integrated system which will ensure farmers know exactly how many fruit are on their trees, when they will be in perfect condition for the consumer, and when to employ the right number of people for picking and packing.

“The end goal is to save costs and improve productivity on farm, while driving consumer demand by ensuring a top-quality eating experience every time.”

CQUniversity researchers are now working to take their mango sensor and auto-harvest technologies to commercial-ready deployment.

Professor Walsh told the conference that the aim now is to improve the performance of the harvester to over 90 per cent efficiency of fruit in view, to increase speed and to refine its construction to reduce cost.

The team started by developing a near infrared spectroscopy (NIRS) measurement system to assess the eating quality of mangos and predict the ideal harvest time.

That work, in the form of NIRS sensors and the Fruitmaps app, are now in use within the mango industry.

The latest experiments have taught machine vision systems to count fruit and estimate fruit size, for fruit load estimates before harvest, allowing farmers to better plan their harvest.

“The next step on from that, having ‘seen’ the fruit, was to try to reach out to pick the fruit to automate the harvest,” Professor Walsh said.

The prototype harvester takes approximately five seconds to harvest a fruit, from detection to placement.

Ian Groves, of Groves Grown Fruit, Yeppoon, hosted the first field trials of the prototype auto-harvester and was excited by the “game-changing” potential of the technology.

“The machinery identifying and counting fruit in the orchard turned out to be within just a few per cent of the actual number of fruit in the entire block last year,” Mr Groves said.

“That technology is also able to measure the size range of that fruit and so knowing how much fruit is in that block, knowing when it’s going to be mature and knowing the size of the fruit, means we can schedule our workforce, order the right number of cartons, the size of the inserts going into those cartons – this could be a real game changer, not only for our farm but for the entire industry.”

More information is available here.

Print

Print